CURVPEEL® Laminated Shims

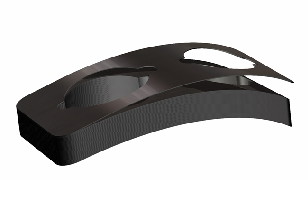

The curved laminated shims

CURVPEEL® is an exclusive innovative process.

It provides a top-quality solution for laminated shims with curved shapes, where the required curve radius is incorporated into the shim during production.

Benefits

Thicknesses & Weights

Benefits of CURVPEEL® peel shims

Optimal Ergonomics

The process is applied to shims intended for use on cylindrical couplings: these shims will then create a perfect fit for the curved configuration sets that are specific to certain assemblies. Cowlings, wind-turbine housings, fuselages, body-work, transmission shaft guides, etc. are examples of this use.

With the CURVPEEL® process, many different types of parts can be positioned and adjusted on curved bodies without any extra fitting being required. Probes, antennae, rear-view mirrors, motors, stabilizers, pump bodies, reduction gear bodies, etc. are all possible examples.

Very High Precision

With the CURVPEEL® manufacturing process, highly accurate curved shims can be obtained with one or more constant radii.

A Gain In Time And A Financial Benefit

The shim no longer needs to be shaped before being assembled: It is delivered ready-to-use. This advantage is all the more appreciable where thick metallic laminated shims are required, as they cannot be curved manually or even with special tooling just before they are assembled.Furthermore, the CURVPEEL® process avoids any risk of delaminating and/or breaking laminations that can be found when shims are shaped at the last moment

This results in avoiding running the risk of considerable losses of time and a reject ratio that may often prove to be prohibitive.

LAMECO’S Specialty: Impeccable Quality

Our laminated shims are composed of foils glued across the entire face and not just at the edge.

In addition, due to our exclusive production processes they are perfectly parallel and totally free of any burrs.

Thicknesses & Weights available for CURVPEEL® peel shims

| Standard / Materials | Specific weight | Thicknesses of laminations in inches / mm Standard | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| STANDARD | AISI SAE |

UNS | EN | BS | ISO | .0002 0,005 |

.0004 0,01 |

.0005 0,012 |

.0007 0,019 |

.0009 0,023 |

.001 0,025 |

.002 0,05 |

.003 0,075 |

.004 0,1 |

.0043 0,11 |

.008 0,2 | |

| Aluminum | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | ||||||

| CPLS1 | 1200 | A91200 | 1200 | 1200 | Al99,0 | 2.8 | √ | √ | |||||||||

| CPLS2 | 5052 | A95052 | 5052 | 5052 | AlMg2,5 | 2.8 | √ | √ | |||||||||

| CPLS18 | 1050 | A91050 | 1050 | 1050A | Al99,5 | 2.8 | √ | √ | √ | ||||||||

| CPLS19 | 1100 | A91100 | 1100 | 1100A | Al99,0Cu | 2.71 | √ | √ | |||||||||

| Brass | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | ||||||

| CPLS3 | C27200, C27700 | CuZn37 | CZ108 | CuZn37 | 8.5 | √ | √ | √ | √ | ||||||||

| Stainless Steel | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | ||||||

| CPLS4 | 302 | S30200 | 1.4300, 1.4310 | 304S31 | 8.2 | √ | √ | √ | |||||||||

| CPLS5 | 304 | S30400 | 1.4301 1.4350 |

304S15 304S16 |

8.2 | √ | √ | √ | √ | √ | |||||||

| CPLS6 | 304L | S30403 | 1.4306 | 304S11 | 8.2 | √ | √ | √ | |||||||||

| CPLS7 | 316 | S31600 | 1.4401 1.4036 |

316S16 316S33 |

8.2 | √ | √ | ||||||||||

| CPLS8 | 316L | S31603 | 1.4404 1.4435 |

316S12 316S13 |

8.2 | √ | √ | √ | |||||||||

| Steel | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | ||||||

| CPLS9 | 1010 | G10100 | 1.1121 | 040A10 | 1010 | 7.85 | √ | √ | √ | √ | |||||||

| Titanium | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | ||||||

| CPLS10 | Ti Gr1 | R50250 | 3.7025 | 2TA1 | 5832-2 | 4.5 | √ | √ | √ | √ | |||||||

| CPLS11 | Ti Gr2 | R50400 | 3.7035 | TA 2 | 5832-2 | 4.5 | √ | √ | √ | ||||||||

| INTERCOMPOSITE® | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | ||||||

| CPLS12 | Polymer / epoxy / polyester | 1.395 | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||

| DUOPEEL® | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | ||||||

| CPLS13* | Metalized polyester | 1.395 | √ | √ | √ | √ | |||||||||||

| X.FIBER® | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | ||||||

| CPLS15* | Carbon fabric | 1.05 | √ | ||||||||||||||

| CPLS16 | PLUS glass fabric | 1.35, 1.37, 1.39 | √ | √ | √ | ||||||||||||

* CPLS14 has been superseded.

For more information:

CURVPEEL®: Trademark Registered, France: FR 1 355 565 B1, Europe: Patent Pending, Canada: Patent Pending, US: Patent Pending.